Collapsible content

■ About ABM

-

ABM - ABM30208C ストップテイルピース用スタッド/アンカーセット クローム(ミリ規格)

Regular price ¥6,380Regular priceUnit price per -

ABM - ABM30208Gaged ストップテイルピース用スタッド/アンカーセット ゴールドエイジド加工(ミリ規格)

Regular price ¥9,020Regular priceUnit price per -

ABM - ABM30208G ストップテイルピース用スタッド/アンカーセット ゴールド(ミリ規格)

Regular price ¥8,030Regular priceUnit price per -

ABM - ABM30208Naged ストップテイルピース用スタッド/アンカーセット ニッケルエイジド加工(ミリ規格)

Regular price ¥7,150Regular priceUnit price per -

ABM - ABM30208N ストップテイルピース用スタッド/アンカーセット ニッケル(ミリ規格)

Regular price ¥6,380Regular priceUnit price per -

ABM - ABM3020CA ストップテイルピース クローム(アルミ製)

Regular price ¥18,040Regular priceUnit price per -

ABM - ABM3020C ストップテイルピース クローム(ベルブラス製)

Regular price ¥18,040Regular priceUnit price per -

ABM - ABM3020G ストップテイルピース ゴールド(ベルブラス製)

Regular price ¥23,650Regular priceUnit price per -

ABM - ABM3020GA ストップテイルピース ゴールド(アルミ製)

Regular price ¥23,650Regular priceUnit price per -

ABM - ABM3020NA ストップテイルピース ニッケル(アルミ製)

Regular price ¥18,040Regular priceUnit price per -

ABM - ABM3020N ストップテイルピース ニッケル(ベルブラス製)

Regular price ¥18,040Regular priceUnit price per -

Sold out

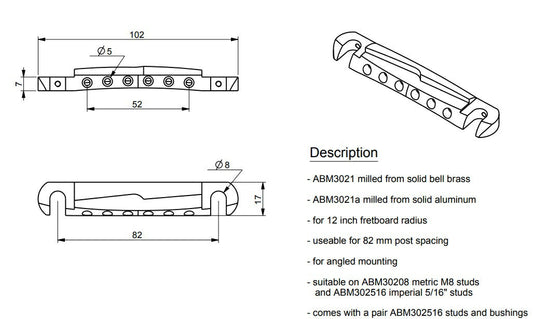

Sold outABM - ABM3021C ラップアラウンドブリッジ クローム

Regular price ¥19,360Regular priceUnit price per -

ABM - ABM3021CA ラップアラウンドブリッジ クローム(アルミ製)

Regular price ¥19,360Regular priceUnit price per -

ABM - ABM3021GA ラップアラウンドブリッジ ゴールド(アルミ製)

Regular price ¥24,970Regular priceUnit price per -

ABM - ABM3021G ラップアラウンドブリッジ ゴールド (ベルブラス製)

Regular price ¥24,970Regular priceUnit price per -

Sold out

Sold outABM - ABM3021N ラップアラウンドブリッジ ニッケル

Regular price ¥19,360Regular priceUnit price per -

ABM - ABM3021NA-aged ラップアラウンドブリッジ ニッケル エイジド加工(アルミ製)

Regular price ¥22,000Regular priceUnit price per -

ABM - ABM3021NA ラップアラウンドブリッジ ニッケル(アルミ製)

Regular price ¥19,360Regular priceUnit price per -

ABM - ABM3022NA ラップアラウンド PRSタイプ ニッケル(アルミ製)

Regular price ¥24,750Regular priceUnit price per -

ABM - ABM3024CA ラップアラウンド 独立サドルモデル クローム(アルミ製)

Regular price ¥32,010Regular priceUnit price per -

ABM - ABM3024NA ラップアラウンド 独立サドルモデル ニッケル (アルミ製)

Regular price ¥32,010Regular priceUnit price per -

ABM - ABM302516B ストップテイルピース用スタッド/アンカーセット ブラック(インチ規格)

Regular price ¥8,030Regular priceUnit price per -

ABM - ABM302516C ストップテイルピース用スタッド/アンカーセット クローム(インチ規格)

Regular price ¥6,380Regular priceUnit price per -

ABM - ABM302516Gaged ストップテイルピース用スタッド/アンカーセット ゴールドエイジド加工(インチ規格)

Regular price ¥9,020Regular priceUnit price per

CONTACT

You can contact us here for new handling, stock confirmation, product inquiries, etc.